- Ekonomiczna 6, 59-700 Bolesławiec

- biuro@sacher-cnc.com

- Tel.: +48 75 734 65 70

WE PROVIDE SERVICES AND SUPPORT

AUTOMOTIVE INDUSTRY

AREOSPACE INDUSTRY

DEFENCE INDUSTRY

We have been a leading CNC machining supplier for almost two decades in our region.We offer the comprehensive range of CNC machining service. Sacher provides a comprehensive offer for all types of CNC machining.We offer a wide range of services for all branches of industry. From a prototype all the way to mass manufacturing, just name it.

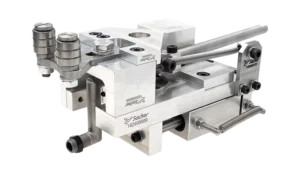

MACHINERY RESOURCES

Quality you can trust.

We are proud of our work and we make sure that every piece is made accurately and precisely to meet your demands. We are willing to accept any challenge! We do more than metal processing.We are proud of our in-depth knowledge and experience. If you are looking to expand your business, we are ready to statisfy all your production demands.

Efficient and effective production.

We are able to meet all your production demands- from concept to production and everything between. From mechanical processing, electrical discharge machining to heat treatment and finally cleaning.

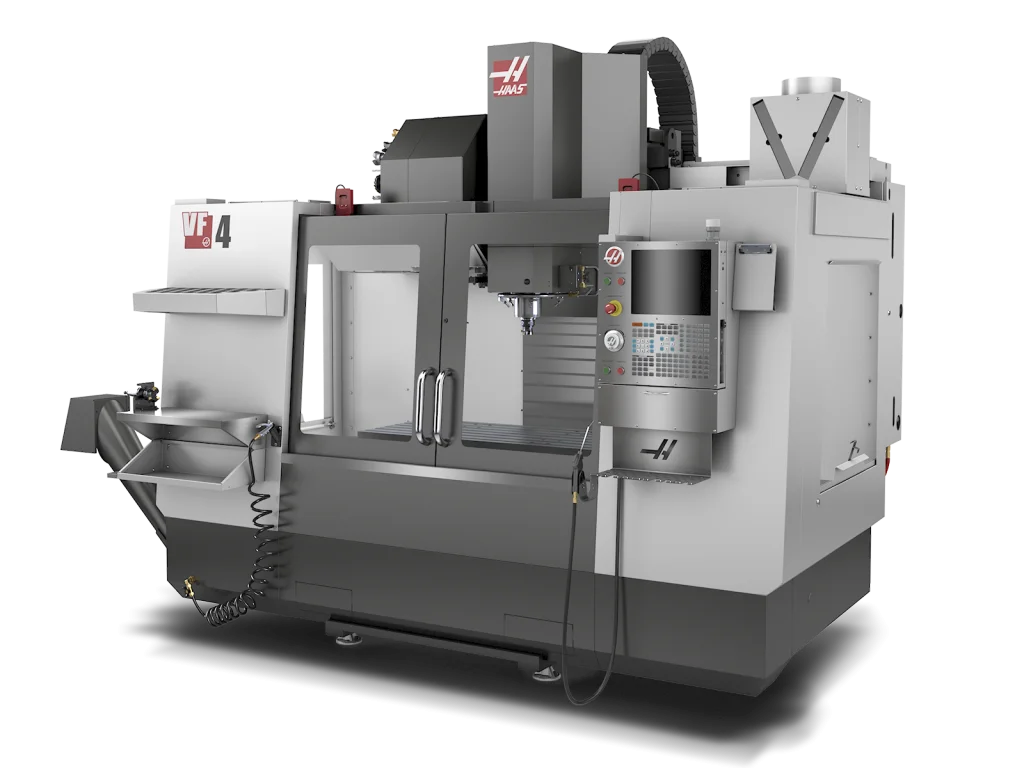

3-AXIS MILLING

HAAS VF2

NUMBER OF MACHINES: 2

HAAS VF4

NUMBER OF MACHINES: 2

HAAS VF5

NUMBER OF MACHINES: 1

HAAS VF2

NUMBER OF MACHINES: 2

HAAS VF4

NUMBER OF MACHINES: 2

HAAS VF5

NUMBER OF MACHINES: 1

5-AXIS MILLING

HERMLE C-400

NUMBER OF MACHINES: 6

HERMLE C-400

NUMBER OF MACHINES: 3

2-AXIS TURNING

HAAS ST-10

NUMBER OF MACHINES: 1

HAAS SL-20

NUMBER OF MACHINES: 1

HAAS ST-10

NUMBER OF MACHINES: 1

HAAS SL-20

NUMBER OF MACHINES: 1

TURNING WITH INTERCEPTION

and driver tools and Y axis

Haas DS-30SSY

NUMBER OF MACHINES: 1

Haas DS-30SSY

NUMBER OF MACHINES: 1

WIRE ELECTRICAL DISCHARGE MACHINING

Mitsubishi MV1200S

NUMBER OF MACHINES: 1

Mitsubishi FA20S

NUMBER OF MACHINES: 1

Mitsubishi MV1200S

NUMBER OF MACHINES: 2

Mitsubishi MV1200R

NUMBER OF MACHINES: 1

Mitsubishi MV1200S

NUMBER OF MACHINES: 1

Mitsubishi FA20S

NUMBER OF MACHINES: 1

DIE-SINKING EDM

Mitsubishi EA12V

NUMBER OF MACHINES: 1

Mitsubishi EA8SM

NUMBER OF MACHINES: 1

AH-35ZA

NUMBER OF MACHINES: 1

Mitsubishi EA8SM

NUMBER OF MACHINES: 1

INTERNAL AND EXTERNAL CYLINDRICAL GRINDING

Studer Favorit

NUMBER OF MACHINES: 1

QA ( QUALITY ASSURANCE)

Our expertise at your fingertips.

We have a team of experienced specialists which is always up to date with the latest innovations in the industry so that we are able to offer you guidance regarding your project. We also have a wide range of specialist equipment and, as a result, each project is designed to maximize efficiency from scratch. Wenzel LH-65 , Wenzel LH-64, Vickers and Rockwell hardness testers, Mitutoyo Profilometer

Wenzel LH-64

NUMBER OF MACHINES: 1

Wenzel LH-65

NUMBER OF MACHINES: 1

MANUAL MACHINES

In our machinery resources, manual machines play an important role; they supplement CNC machines. We have at our disposal the following manual machines: – shaft grinders – shafts for inside rotary surfaces – universal shafts – manual lathes

HEAT TREATMENT

One of our biggest advantages is our own quenching plant, which gives us a high degree of flexibility and dynamics with respect to order execution. We have two vacuum furnaces, in which the following processes are carried out: vacuum hardening in oil 750-1300°C vaccum carburising 850-950°C vacuum tempering 150-700°C plasma nitriding 500-650°C Charge dimensions : 450x450x600mm – 250kg.

CERTIFICATES

Guaranteed quality

Our commitment to provide quality products has helped us to acquire hundreds of satisfied customers over the years.

ISO 9001:1

ISO 9001:1